• Reduced mould release failure from 80% to 0%

• Reduced set-up costs by 70%

• Increased gross margin by 25%

• Consistent visual quality throughout run

Customer challenge: Unacceptably High Scrap using traditional mould release spray.

ENBIO’S solution: ENBIO’s COBLAST PRO-RELEASE is a permanent mould release coating that allows consistently easy release without liquid agents.

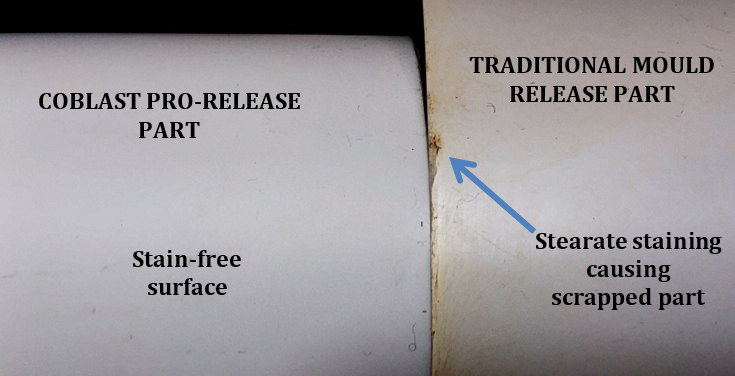

Martin’s Rubber developed a specific white-coloured silicone rubber to match demanding customer specifications. Traditional mould release agents caused unacceptable scrap due to discolouration and water marking (see image below). ENBIO’s COBLAST PRO-RELEASE removed these problems and eliminated mould release failure scrap from >80% to 0%.

Martin’s Rubber put the coated tool straight into production and got parts right-first-time, reducing set-up costs by 70%. The parts released more easily, consistently, and without any discolouration or watermarking. They commented that “the coating is great! The moulded part flew out of the cavity, perfect release, very happy”.

Right: Part produced using stereate mould release showing yellow discoloration.

Benefits

• Long lasting, damage tolerant, robust coating with excellent release.

• Applicable on virtually all metal types (including steels, aluminium, invar, etc).

• Consistent visual aspect of moulded part- no discolouration or visual defects.

• Reduced expense, time and effort during tool use (no additional mould release agents use, no drying / curing time of coating).

• Improved environmental conditions in Production with no volatiles or aerosolized mould release sprays.

• Silicone-free product.